Product Development

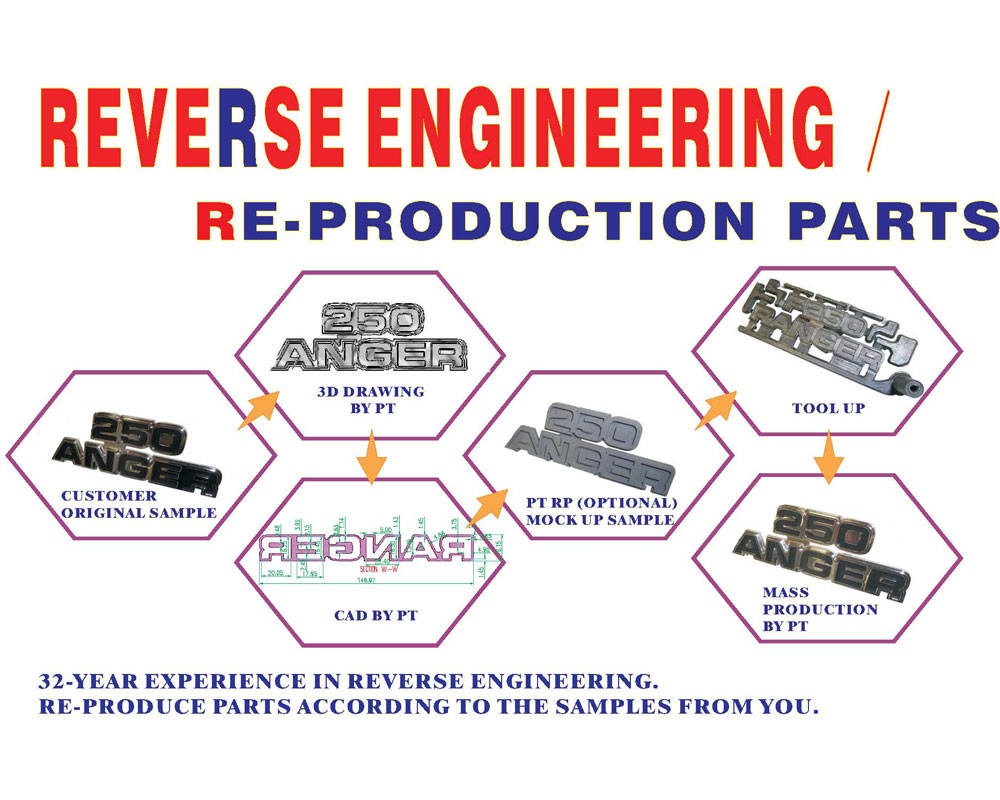

At Pan Taiwan, we specialize in reverse engineering services and comprehensive manufacturing solutions, offering over 4,000 successful projects for clients worldwide. Since 1977, we've been a trusted partner, particularly for customers in the United States and Western Europe. Our expertise extends across various industries, including assembly, die casting, metal forging, machining, plastic injection, rubber molding, and sheet metal stamping. We focus on collaboration, precision, and efficiency to ensure your projects are executed seamlessly. Our tailored services include R&D coordination, streamlined production management, and custom packaging and label design, guaranteeing the highest quality in every product.

Online Showroom

With years of experience, Pan Taiwan has accumulated a great sense toward classic car. Moreover, our subcontractors cover several manufacturing processes, such as plastic injection, stamping, rubber molding, die casting. We are especially good at metal stamping, high quality polishing, and chrome parts. Combining the rich experience and multiple skills of manufacturing, Pan Taiwan can definitely reproduce parts exactly same as your request. Until now, we have reproduced more than 5000 parts for our customers.

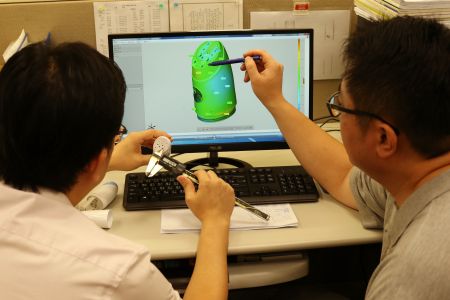

Analysis of Drawings

Duplication starts with the analysis and evaluation of drawings. Based on the drawing that our customers offer, our professional RD team will be evaluating the possible process that this items will require, for example, plating, plastic injection, or molding.

Collaborative Factory Selection

With the analysis and evaluation by our professional RD colleagues, they will decide the matched factories which are suitable for conducting this project for us. If the project is necessary, it can take several factories to finish a projects. For example, we may need factory A to help with the plastic parts, and the other helps with the metal parts. Therefore, we can make sure that every details of this products are well taken care of.

Your Trusted Partner for Development

During the process of reverse engineering, Pan Taiwan will be your perfect partners, who is in charge of supervise the whole process of the development of that parts and give you feedback as soon as possible. Moreover, at the same time, Pan Taiwan is also available to handle labels or packing for you. In our previous cases, we used to help with our customers design their label on their switches. With the assistance of our art department, we can assure that the label will look exact the same as your expectation.

Collaborative Success with Pan Taiwan

To sum up, a successful duplicated products will take lots of people’s works and cooperation. Pan Taiwan may not be available at every specific techniques, however, we can use our experience to accomplish the same result. The advantages we get include the experienced partnered factories of each kinds of techniques, years of experience when evaluating the your projects, prompt and clear communicative with our sales representatives, and well developed functions of one-stop shopping service. At Pan Taiwan, all of your needs can be well taken care of and all of the requirement will be noted. Therefore, please don’t hesitate to send us your inquiries to our email. We wish to develop more and more discontinued parts with you in the future.

Assembly Work

Sometimes we receive the request of building a product but not just a part. In this case, we will...

Details Add to ListDie casting

DIE CASTING is one of our mostly used production processes for reverse engineering. It is commonly...

Details Add to ListMetal Forging

Forging is normally used for chassis parts such as ball joint, control arm, suspension arm and so on. Therefore,...

Details Add to ListMachining

Oftentimes we would make pins, brakets, brass block and valves for customers by machining process....

Details Add to ListPlastic injection Molding

Our plastic injection molding service is done by a professional team of experienced and skillful...

Details Add to ListRubber Molding and Extrusion

Rubber parts is extensively used in cars. From seal, engine mount, boots, weather strip, door...

Details Add to ListSheet Metal Stamping

One of the last manufacturers to embrace the metal stamping of automobile parts was Henry Ford,...

Details Add to ListProduct Development - Various developments for different product | Over 40 Years Aftermarket Auto Parts Manufacturer And Exporter | Pan Taiwan

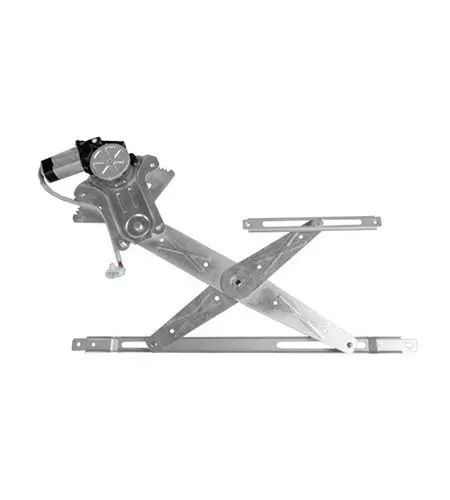

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been an aftermarket auto parts manufacturer and exporter. Their main products include, Product Development, window regulators, car mirrors, window crank handles, window seals, door handles, windshield wiper blades and windshield wiper arms with ISO 9000 certification.

Pan Taiwan have 40 year experiences in supplying aftermarket automotive parts. We provide more than 3,500 models of window regulators in many brands, and 2,000 different items for classic cars. We have reproduced almost 2,000 products upon request of customers so our sales and engineers have perfect understanding and are very good at reverse engineering old parts. With more than 40 years xperiences in supplying aftermarket automotive parts, Pan Taiwan has excellent understanding in what customers need in reproduction and good sense in quality control.

Pan Taiwan has been offering customers window regulators, classic car parts and reverse engineering services, both with advanced technology and 40 years of experience, Pan Taiwan ensures each customer's demands are met.