QA & QC

Pan Taiwan Quality Assurance and Quality Control System

Pan Taiwan has been ISO 9000 certified since 1996, and we go beyond the standard requirements to ensure true quality excellence. Unlike many ISO-certified companies, we uphold two core principles that set us apart.

First, we are committed to continuous improvement-refining and enhancing our quality procedures year after year. Second, we emphasize internal understanding and accountability: all staff members are required to thoroughly understand ISO standards and our internal Quality Procedures (QP), and to apply them consistently in their daily work.

In addition, every employee completes two rounds of 4-hour training sessions before qualifying as an internal auditor. This company-wide engagement ensures a strong quality culture and helps us maintain the highest standards across all departments.

Ensuring Product Quality Through Professional R&D and QC

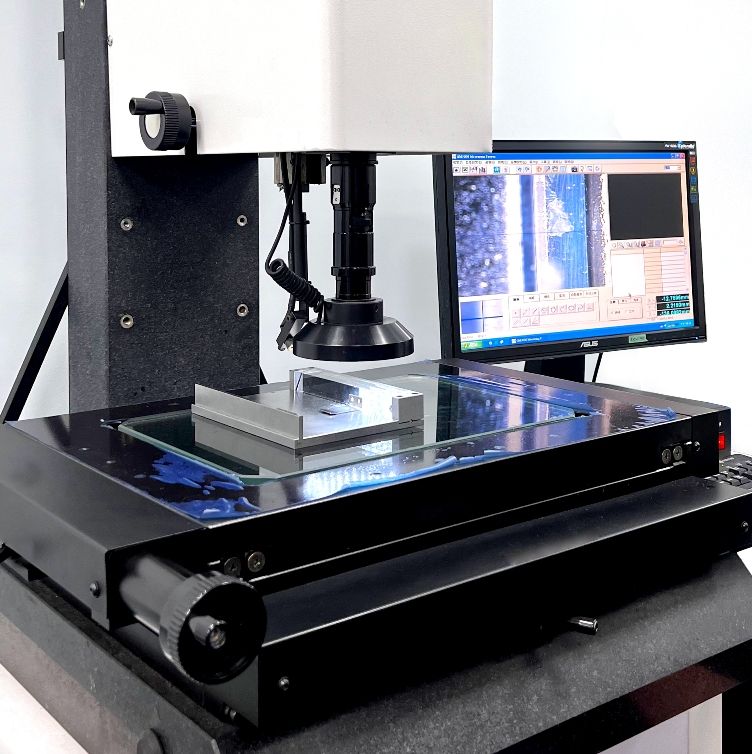

At Pan Taiwan, our experienced R&D and Quality Control (QC) teams—each with over a decade of expertise in the automotive industry—play a crucial role in ensuring product quality.

Our R&D team begins by evaluating customer-provided samples or drawings. Once order details are confirmed, we proceed with the development of a T1 (Trial 1) sample for customer approval. Based on the approved sample, the R&D team prepares detailed work instructions to guide both the production and QC processes, ensuring consistency and clarity across all departments.

Our QC team conducts thorough inspections at each critical point and generates detailed inspection reports, available in either Chinese or English. To maintain quality traceability, we also retain reference samples from each shipment as part of our sample archive.